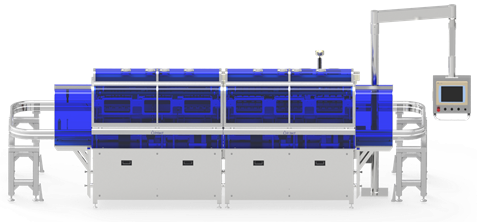

INTACT™ Modular Filler (IMF)

1-Module INTACT™ Filler

2-Module INTACT™ Filler

The Intact™ Modular Filler (IMF)

The IMF is a fully integrated, automatic filling machine performing all filling activities, including container loading, positioning, filling, and container unloading. The IMF can fill glass or plastic containers of various shapes and sizes (bottles, vials, pouches) with high precision and consistency.

The IMF is modular with interchangeable modules for various filling process functions. As a result, the filler:

- is easily installed and maintained with minimum change parts

- dramatically simplify product change over and cleaning validations

- is adaptable to various filling process requirements for different customers

- is capable of filling any of the Intact™ devices without any alterations

- is scalable for desired output

- has no rotating parts and only two moving parts:

- The carrier, which runs through the filler on a conveyor (horizontal line)

- The needles, which move up and down to pierce the port on the container (vertical line)

IMF is Compliant.

The preservatives typically added to products to destroy potential contaminating germs, are unnecessary because of the physical barrier which prevents contamination. This means higher patient/customer safety level, and compliance has been engineered thanks to container design, filling process and dispensing technology. Representatives of Regulatory agencies have voiced their support of the Intact™ Filling System and described it as “the paradigm shift in aseptic filling technologies”.

IMF is compact.

A typical IMF has a foot print of 75 sqft and requires a room of 150 square feet.

IMF is a complete turnkey system: with a single electrical connection, the IMF is a fully integrated filler without the need of vaporized hydrogen peroxide (VHP), air compressor or complex and costly isolators.

IMF has a significant filling capacity.

An IMF with 4 heads per station has a filling output of up to 15 million containers a year, using a three shift operation, while filling 100 ml per container.

Advantages of the Intact™ Modular Filler

Simple design.

Unlike in conventional fillers, there is no assembly of caps, no cap tightening and no rotating parts. As a result, the IMF is simpler to operate and more reliable, which makes the IMF superior to conventional fillers.

Sterile fill.

Containers are always functionally closed, eliminating risks for contamination: the IMF leads to trillion times less exposure than traditional aseptic filling of open containers.

Ability to fill in non-sterile environment.

Sterile filling successfully documented in a log3 bio-burden environment (equivalent to a sneeze or a dirty pig stable). As a result, the filler doesn’t need to be enclosed in a “clean” room.

Preservative free formulations.

Since the container is always closed, the formulations are not only filled sterile but they also remain sterile from first to last dose, removing the need of preservatives. This means higher patient/customer safety level, and compliance has been engineered thanks to both container design and filling process.

Foamy formulations.

Since the container is always closed eliminating any splash incidence, the IMF is particularly suited to fill formulations which tend to foam.

Blending.

IMF can also blend products during the filling process. Since the proprietary elastomeric re-sealable stopper can be pierced safely several times, the IMF can independently fill several components into devices, allowing different sensitive components of a formulation to be mixed in the devices during the filling process.

Just In Time Filling.

At the push of a button, the formulations stored in different tanks can be programmed-filled at several filling stations, making the IMF a versatile and multi-purpose filler.

Simplified regulatory compliance.

Regulatory compliance has been engineered into the filling machine. Since the containers are always closed, the product lines and filling needles are single run disposables, and there is no possibility of splash and leaks during filling, the filler remains always clean, eliminating the need for extensive cleaning and sterilization, and media fills at each product change over thus dramatically reducing line down time and costs.

Custom designed.

Thanks to its simple, modular design, the IMF can be custom-designed as per customer specifications.

Low capital investment.

Since there is no need to create a clean and controlled environment around the IMF, the capital investment to house the filler is dramatically less than the one required for an Aseptic plant. Also, thanks to its simplicity and modular design, the IMF cost is significantly less than today’s aseptic fillers.

Low operating costs.

The operating costs to run the IMF (less procedures, less cleaning steps, less operators, less monitoring, less splashes, less down time, faster installation) are significantly reduced compared to traditional aseptic filling of open containers. The number of operators is also reduced and there is no need for a team of aseptic specialists to maintain and monitor the filling suite. Moreover, a single operator can run several machines at the same time.

Applicable to Hospital and Laboratory operations.

In its smaller form, the IMF makes compounding in hospitals and pharmacies significantly safer. The equipment can also be used in laboratories and development facilities for sterile formulation development, master seed preparations, and aseptic biological sample aliquoting. With a single electrical connection, no vaporized hydrogen peroxide (VHP), no air compressor, no complex and costly isolators, the IMF is ideal for such applications.

Applicable in emerging countries.

The IMF is an elegant and efficient filling solution for emerging countries, which do not typically have available aseptic clean rooms nor trained operators for aseptic procedures. The IMF gives access to safer medicine and healthy liquid food to their growing emerging world populations. By implementing the IMF, emerging countries can advance from “clean” filling to sterile filling, by-passing the need for expensive and inefficient aseptic filling available today in developed countries.