INTACT™ Connectors

Most connectors today are not 100% closed to the environment and as a result do not guarantee 100% of the sterility of the fluid path. A few closed connectors are currently on the market; however they are all for single use, made of a multiple parts, require multiple connecting steps and are expensive.

The Intact™ Sterile connector is the FIRST multiple-use sterile connector in the world. For the transfer of any liquid, the Intact™ connector is the ONLY multiple-use sterile connector, which guarantees no contact between the liquid path and the external environment ensuring no ingress of air, bacteria, yeasts or molds.

The INTACT™ Sterile connector is a major breakthrough for every industry and setting requiring transfers of fluids under sterile conditions without a controlled environment including the Pharmaceutical, Bioprocessing, Healthcare, Liquid & Beverages industries. These connectors are scalable in size to meet the demands of virtually any requirement.

The INTACT™ Sterile connector is currently available in two sizes:

- a larger one for industrial applications

- a smaller one for enteral and parenteral applications

The INTACT™ connector has been engineered to be sterile, multiple-use, safe, convenient, environment-friendly, and reasonably priced.

Sterile

The Intact™ Sterile connectors allow sterile transfers and connections in contaminated environments between any two containers and more generally from any recipient to another recipient/beneficiary, for example from a pouch to the arm or mouth of a patient, etc.

Multiple-use

Microbiology tests and various seal challenge tests have proven that the Intact™ Sterile connectors prevent the contamination of fluid transfers even after several connections and disconnections in a bio-burdened environment.

Safe

The Intact™ Sterile connectors are “safe” for both the liquid and the operator and his/her environment. It prevents:

- the liquid from being contaminated by the environment

- the operator from being contaminated by the liquid

Convenient

With only two ends (male and female), and no need to clamp or weld, the Intact™ Sterile connector is easy to connect and disconnect.

Cost

All Intact™ Sterile connectors have been engineered with cost savings in mind. Depending on the configuration, Intact Connectors are molded in 2-4 parts. As a result, the Intact™ Connectors do not add any significant expense over the “dirty” connectors currently used in manufacturing or healthcare settings.

The Intact™ Sterile connector performed various seal challenge tests using:

- Valve opening pressure: Measurements showed the Intact™ Sterile connectors are adequate for perfusion/gravity based feeding applications as well as for pump based applications requiring a higher pressure.

- Electro-conductivity: Tests demonstrated that the male/female connectors provided seal to prevent electrical conduction between the protected inner structure and the exposed environment. Once connected, the Intact™ Sterile connectors created a path for electrical conduction between container and recipient. After disconnection, conductivity disappeared between male and female connection.

- Test Microbial organisms: Microbial challenge tests were conducted prior to, during and after connection in a purposely contaminated enclosure using various concentrations of B. subtilis, B. diminuta and E_. aerogenes_ in aerosol form and liquid form. Sterile Product was pumped through the DROC connection, followed by incubation, sampling, streaking, incubation and observation/count of growth of microbes. No growth was observed from the test samples and was verified by appropriate positive and negative controls.

- Functional tests: Assembly force and flow rate measurements were also conducted on the various Intact™ Sterile Connectors.

Intact™ Sterile Connectors are designed with customers’ ease of use in mind as well as cost. With three different technologies available to achieve single and multiple use connections, MedInstill is setting the new standard in Sterile Transfers. These technologies are designed to be used in Industrial, Manufacturing & Healthcare (enteral and parenteral) settings. Available in disposable or multiple use, these connectors enable customers to ensure sterile transfers in contaminated environments.

The Intact™ Sterile connectors have numerous applications:

Hospital-acquired-infections (HAIs)

One of the greatest challenges for the US health care system and the care of veterans, servicemen and women, and their families is hospital-acquired-infections (HAIs). The introduction of infections into predisposed patients during their medical care has catastrophic consequences, leading to additional injuries/complications, which require extensive treatment, and sometimes result in death.

According to studies published by the US Center for Disease Control and Prevention (CDC), there are 1.7 million cases of HAIs resulting in 100,000 deaths and $28-$45 billion in costs per year, in the US alone (Klevens, R. M., et al., Estimating Health Care-Associated Infections and Death in US Hospitals, Public Health Reports, March-April 2007, vol 122 / Estimates for 2002). While there has been significant investment/efforts expended to develop therapeutics against HAIs, the better approach is devices that prevent HAIs in the first place. “The fact that 25-50% or more of nosocomial infections are due to the combined effect of the patient’s own flora and invasive devices, highlights the importance of improvements in the use and design of such devices.” (Robert A. Weinstein: Healthcare-Associated Infections, in Harrison Principles of Internal Medicine, 17th edition, 2008 p837)

According to the CDC, the number of infections is directly correlated to the number of connections.

There has been significant effort focused on the development of novel antibiotics including host-based approaches to microbial infections. While these approaches have a positive impact on treating HAIs, there remain a number of issues including the evolution of drug resistant strains. As such, investment in technologies that prevent the infections should be preferable to those that treat them.

The Intact™ Sterile connectors are an inexpensive yet robust and easy-to-use device that can prevent HAIs. In particular, the connector has multiple medical applications including (i) the sterile delivery of IV fluids, (ii) maintaining the sterility of catheters and (iii) facilitating sterile aphaeresis and dialysis.

Specific applications of the technology could be applied to intravenous fluid and drug delivery, central venous catheters, urinary tract catheters, peritoneal dialysis, hemodialysis, and parenteral and enteral medical feeding. Virtually any scenario where a dose is delivered, where patients are connected to a fluid reservoir, or where containers are connected to each other will benefit from this technology. It is also complementary to other approaches to reducing or treating HAIs, including therapeutics and implementation of infection control practices.

Material Transfer in non-controlled environment

Most industrial activities happen in non-controlled environment. As a result, sterile transfer of any fluid is a major problem and often not possible. With the Intact™ Sterile connectors, sterile transfer is now possible anywhere at a very inexpensive cost. Overtime, new applications will be developed, but one can imagine an Intact™ Sterile connector to transfer fluids from a ship to a truck, from media bottle to a petri dish, etc…

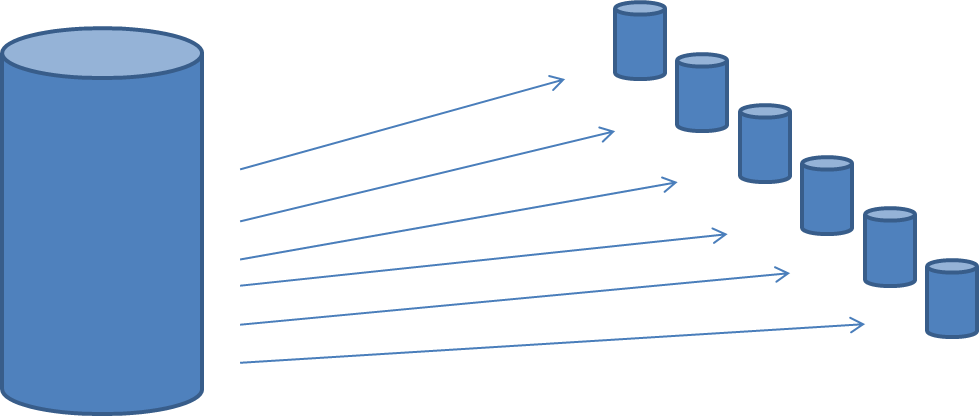

Material Transfer/Aliquoting

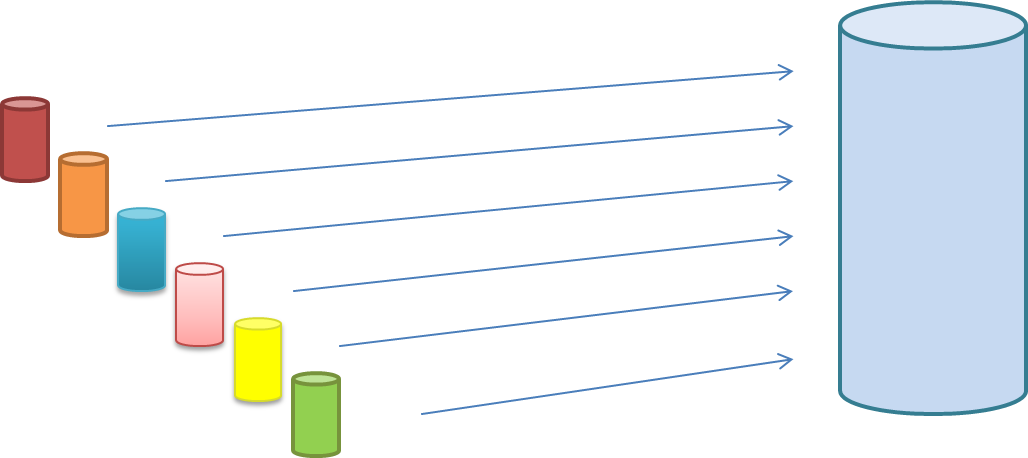

Blending in non-controlled environment

Since the Intact™ Sterile connectors can be connected and disconnected multiple times, different sensitive formulations can be added to the same container. As a result, formulations stored in different tanks can be blended to the same container under sterile conditions.

Blending

Diagnostics

One of the challenges in diagnostics is the cross contamination of samples during the handling and testing. With an Intact™ Sterile connector, false positives are significantly reduced since the original fluid sample remains sterile during its transfer.

Green Environment and the replacement of disposable containers

The Intact™ Sterile connector makes virtually all containers rechargeable. With the new culture of environmental responsibility, throw-away and disposable containers are under strict scrutiny by consumers and packaged goods companies. The Intact™ connector is the solution to significantly reduce waste and recycling by allowing the re-use of containers multiple times.

Pharmaceutical and bioprocessing

The Intact™ Sterile connectors enable:

- Transfers (inoculums, sterile liquids, sensitive biologicals)

- Sampling (fermentation process, cell culture, microbiology…)

- Industrial Equipment Connections (small sterile equipment to large equipment such as bioreactors, tank to filling line, disposable systems)

- Sterile fluid path even in a non-controlled environment

- Sensor insertion into bioreactor